RYOSHO developed ultrasonic inspection equipment by much experience and high technique. It delivers safe and secure to the society.

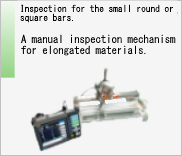

Ultrasonic inspection equipment is non-destructive inspection system. It use for material defects inspection, internal defects inspection, penetration inspection, crack inspection, and automotive parts inspection. And also use for thickness measurement, anchor bolt length measurement, and bolt axial force measurement.

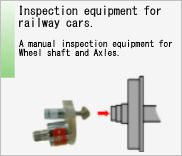

Ultrasonic inspection equipment is widely used maintenance inspection equipment, for trains, traffic-related system, steel bridges, petroleum chemical plant, thermal power generation, and nuclear power generation facilities.

Non-destructive inspection has contributed widely to the safety of infrastructure.