- Built-in temperature compensation.

- Calibration of measurement and maintenance function is equipped.

- Arithmetic functions such as constant axial force is equipped.

- You can calculate the parameters required to measure axial force by UI-27AF.

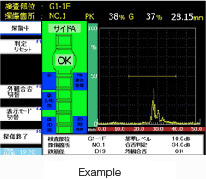

- UI-27AF brings you high reliability when measuring ultrasonic echo waveform display, arrow display of measurement and position measurement.

- Manage data before and after the tightening axis force measurement and accumulation function allows the axial force control for long periods in the axial gauge unit.

![]()

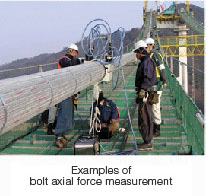

Bolt axial force measurement for bridges and other structures,

Historical axial force management is possible.

![]()

Dedicated ultrasonic flaw detector for reinforced concrete with deformed steel bar by gas pressure welds

Complies with the JIS standard

Comply with ultrasonic flaw inspection test for reinforced concrete deformed steel bar gas pressure welds and determine standard JIS Z 3062 2009.

Automatic sensitivity calibration

Auto-calibration based on peak waveform.

Easy to read results display and one-touch save

Select test results from two types of view mode level display or a reinforced display and press ENT key to save test results.

Result screen and inspection results saved in SD card by bitmap images.

Also ultrasonic flaw inspection capabilities (optional) can be added.

It is possible to inspect welding fittings and mechanical joints. Also possible to use general ultrasonic testing and various ultrasonic testing like wall thickness measurement.